AUTOCLEAN – fully automated

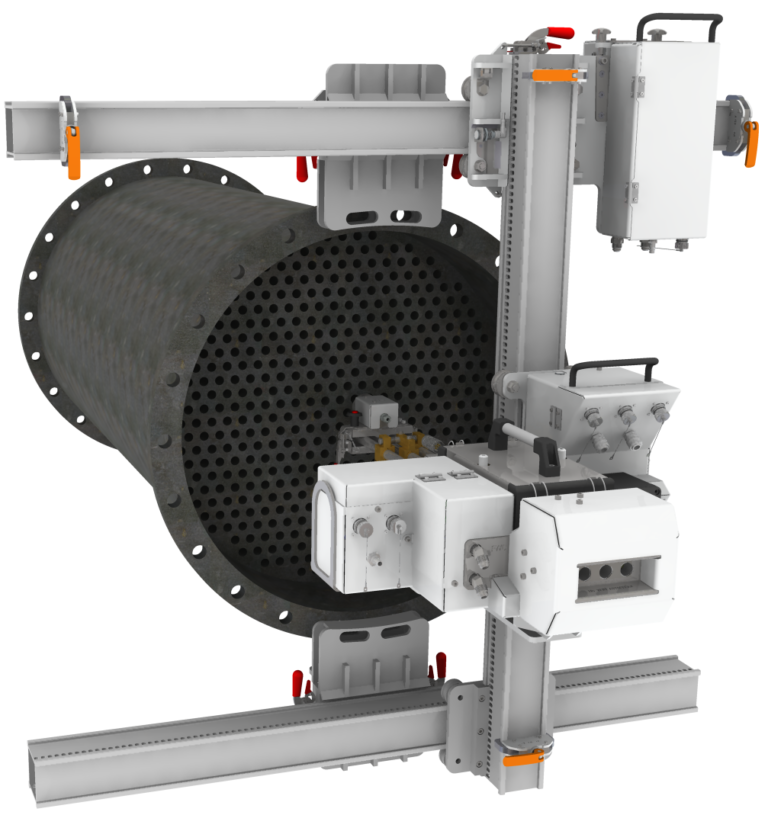

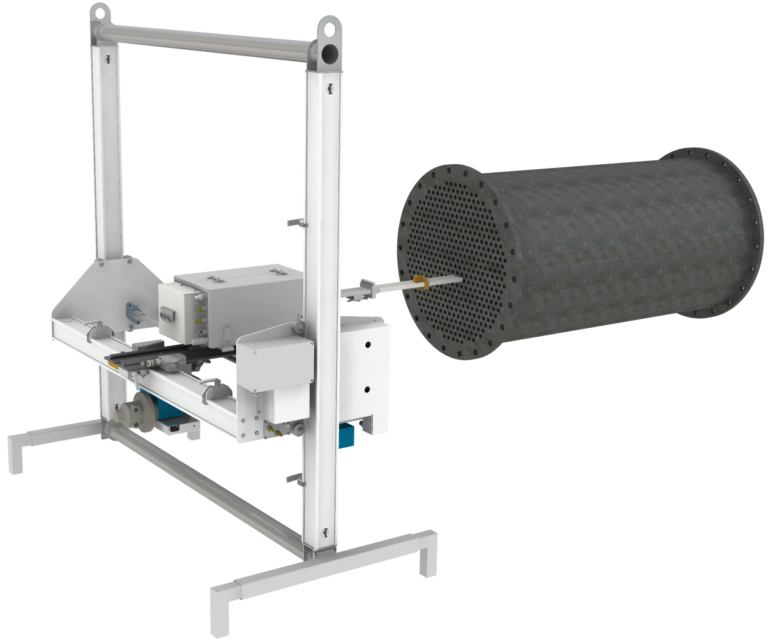

With AUTOCLEAN, tube bundle heat exchangers can be cleaned fully automated with high-pressure water. The operator attaches the machine to the heat exchanger, configures it in a few minutes and then monitors the cleaning process from a safe distance. A high-performance computer controls the machine and shows all relevant information for the operator on a display.

AUTOCLEAN is the pinnacle of the evolution of heat exchanger cleaning with high-pressure water. In the past, cleaning was usually done manually with hand-guided lances, but today semi-automatic cleaning is usually the standard. AUTOCLEAN turns semi-automatic heat exchanger cleaning into fully automatic heat exchanger cleaning.

AUTOCLEAN in action

Heat exchanger cleaning with AUTOCLEAN

Heat exchanger cleaning

Working with ultra-high pressure water in industrial cleaning is challenging for cleaning personnel in many ways. The work often takes place in confined spaces and fog additionally impairs visibility. Hazardous substances are released during the cleaning process, so that often extensive and uncomfortable protective equipment has to be used.

To make this type of work more pleasant and above all safer for the cleaning personnel, Triovent GmbH launched the AUTOCLEAN 2-LTC in 2016, the world’s first fully automatic cleaning machine for heat exchangers.

This makes it possible for the operator to clean the inside of heat exchangers in an absolutely safe environment, while effectively improving the cleaning result.

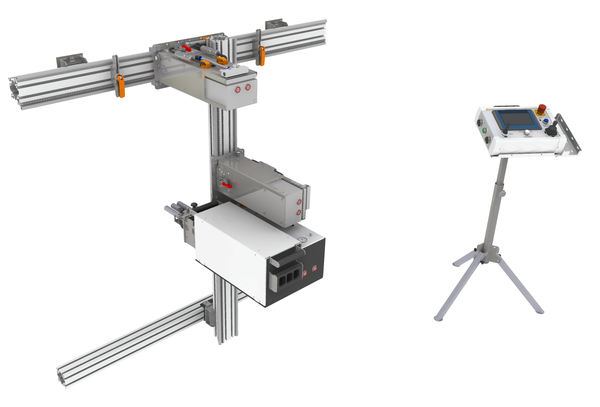

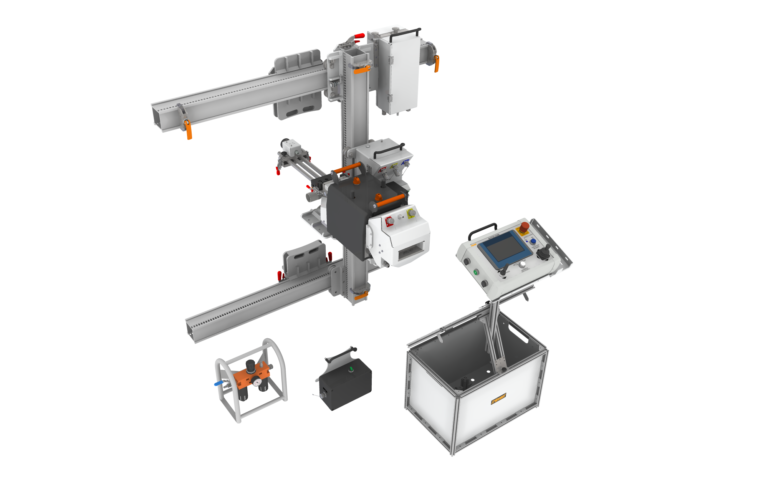

Modular design

The AUTOCLEAN system is designed in such a way that it can be easily adapted to a wide variety of basic machines due to its modular construction. The modules can be adapted to an existing system, thus enabling subsequent automation.

Due to the flexible design it does not matter how many or what kind of hoses and lances are used in the basic machine. Rigid and flexible hoses and lances can also be used without difficulties. The range of movement is therefore only determined by the length of the rails of the basic machine and the hoses.

Automatic

The term „automatic“ is used very inflationary on the market. For instance, manually operated systems are often offered as „automatic“.

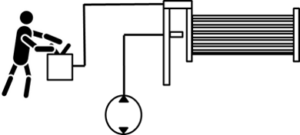

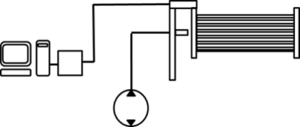

With AUTOCLEAN the name says what it is. The system works automatically without the involvement of the operator. The operator only has to install and configure the system. The setup does not take more than 10 minutes. Afterwards the operator only has an observing function.

Of course, the operator can still intervene in the process if necessary.

Workflow with AUTOCLEAN

Heat exchanger cleaning is easier with AUTOCLEAN. All the advantages of a semi-automatic machine are available. The assembly is done just as quickly.

AUTOCLEAN connects robust air motors with powerful electronics. This combines the advantages of both worlds. The machine can easily be transported, assembled and controlled by a single person. The electrical energy is supplied by a rechargeable battery, regardless of the ambient conditions on site. In contrast to purely pneumatic controls, the machine reacts to control commands without delay due to the chosen arrangement of the components. At the same time, only two lines run from the machine to the control unit, which ensures a tidy and clear working environment.

The configuration of the machine after installation is also quickly completed. The machine guides the user through the three necessary steps via the touchscreen display:

-

Set the diameter of the heat exchanger via four end stops.

-

Set the length of the heat exchanger by moving the hoses.

-

Determine the tube pattern on the heat exchanger surface. Fully automated with the sensor module or manually with the teach-in wizard.

AUTOCLEAN is now set up for fully automatic operation and cleaning can begin.

AUTOCLEAN is…

- - enormous increase in safety (distance of 10 m or more)

- - visual contact to heat exchanger surface not necessary

- - immediate shutdown of the machine if required

- - movement while the hoses are still in the heat exchanger is prevented

- - exceeding of configured end positions is prevented

- - fast and consistent cleaning

- - automatic generation of a log file

- - configured and scanned in only 10 minutes

- - shortest ways from tube to tube

- - most effective method to break through blocked spots in the tube

- - fully automatic cleaning with only a few clicks on the display

- - intuitive user interface

- - no teach-in and no programming necessary

- - without additional effort to install the system

- - self-contained operation with battery possible

- - easy adaptation to a wide range of basic devices

Fully automated cleaning

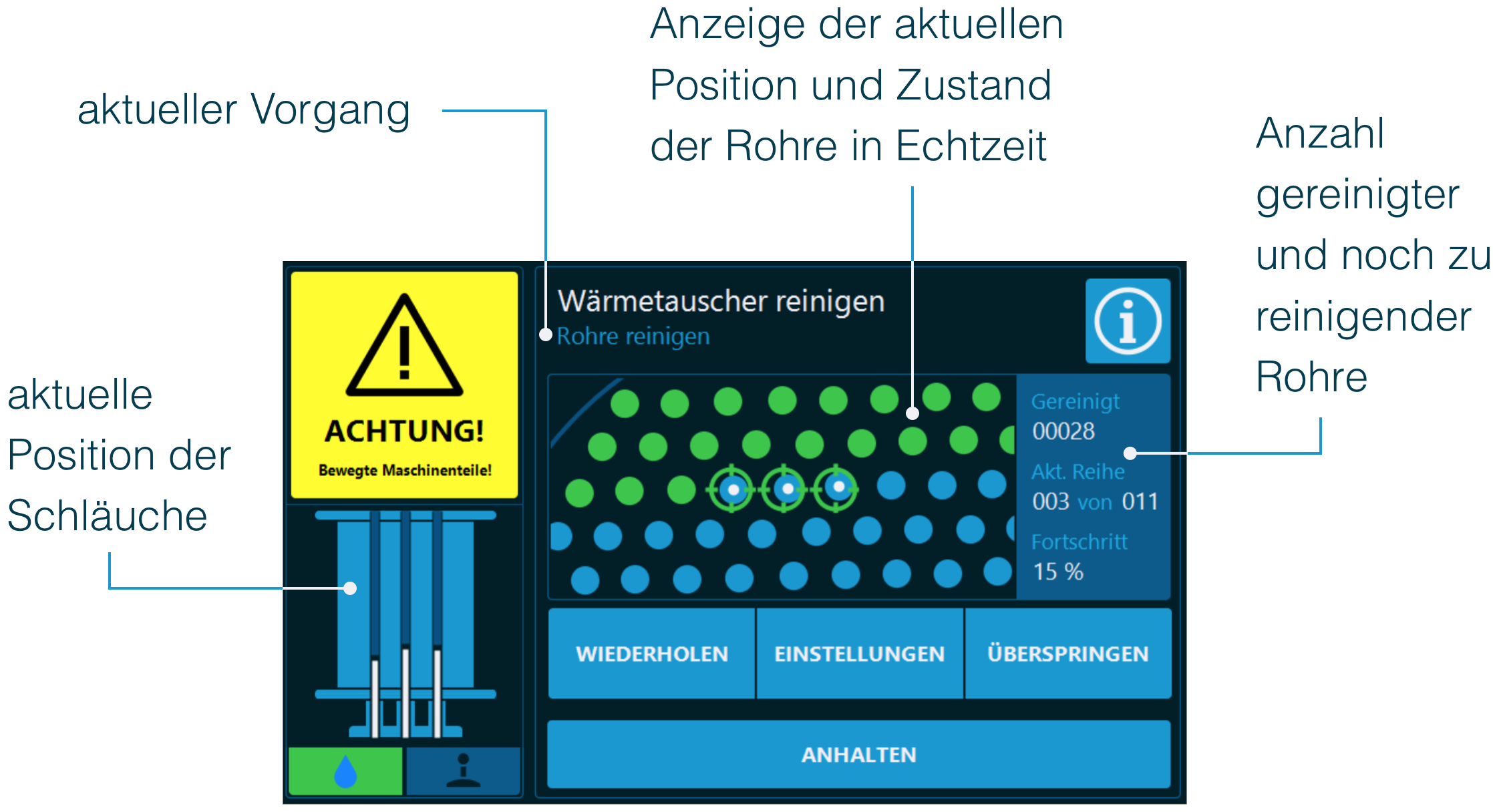

During fully automatic cleaning, the user does not need to press a single button, but can still influence the machine’s behavior at any time.

INDEPENDENT

The machine cleans the heat exchanger automatically by positioning the cleaning lances in front of the pipes and pushing them in. At blocked spots in the tube, the hoses are moved in an oscillating motion to efficiently loosen the contamination.

INFORMATIVE

During the whole process the operator is informed about the current process, the position on the mirror and within the heat exchanger, the condition of the tubes, the duration and much more.

AUTOCLEAN - Varianten

In addition to our AUTOCLEAN 5, AUTOCLEAN is also available as an upgrade for various machines from Peinemann Equipment. Upgrades for other machines are available upon request.

AUTOCLEAN 5

AUTOCLEAN TLX

AUTOCLEAN 3-TLE

AUTOCLEAN 3-XLC