AUTOCLEAN 5 - Everything from a single source

AUTOCLEAN 5 is the first system completely developed by Triovent for fully automatic cleaning of shell and tube heat exchangers. This meant that no compromises were necessary and all the experience Triovent has gained with the use and conversion of manually controlled machines could be used.

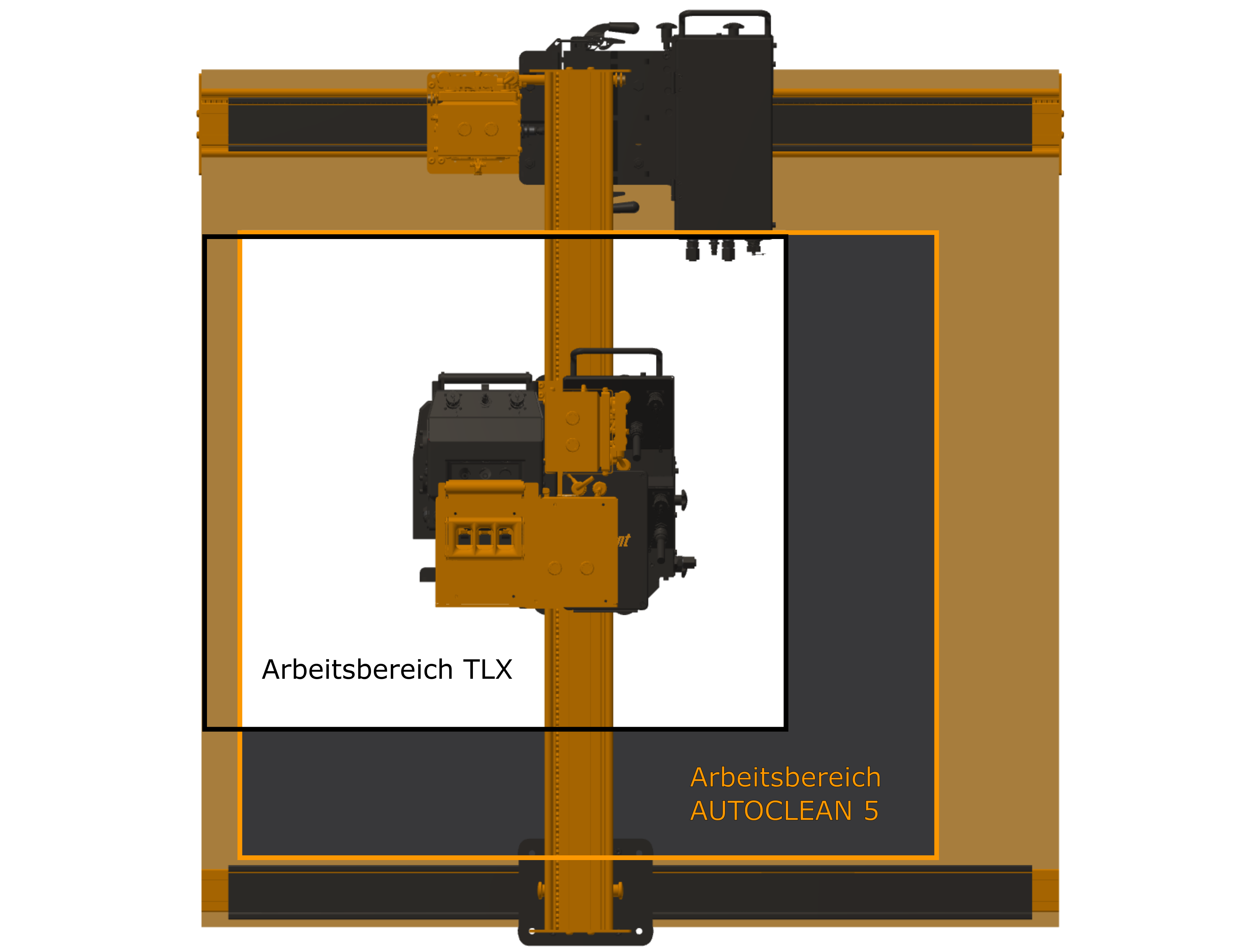

Small machine - Large work area

AUTOCLEAN 5 requires considerably less space than comparable machines and the predecessor model due to the compact integration of the automation components. Compared to an AUTOCLEAN TLX (and the basic model), approx. 30 cm more working area can be used in each direction with the same rail length.

The rail system is available in any length and the individual rails can be easily extended. This allows AUTOCLEAN 5 to be flexibly adapted to the ambient conditions on site.

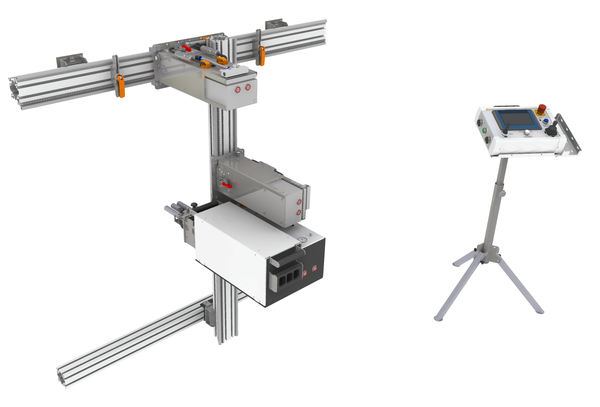

Compact control unit - long-lasting battery

AUTOCLEAN 5 features the proven AUTOCLEAN control unit (5 kg) and comes standard with a 15-meter cable for connection to the machine. The compact foldable stand can also accommodate a tablet for wireless control of non-safety-related functions. This allows the AUTOCLEAN system to be operated at any time from a safe distance from all high-pressure parts.

AUTOCLEAN 5 is supplied on request with a battery case (7 kg) which supplies the entire machine with energy for more than 12 hours and thus allows work independent of the mains. Power can also be supplied via a conventional 230 V power connection.

Easy to set up - Quick cleaning

AUTOCLEAN 5 is just as quick to set up as purely mechanical gantry solutions. The sophisticated design with integrated cable routing ensures a tidy work area without tripping hazards. Only two lines lead to the machine and there is no need for a large and heavy distribution box. All connectors are molded watertight to prevent confusion.

AUTOCLEAN 5 positions the lances exactly in front of the pipes to be cleaned, quickly, precisely and persistently. Therefore AUTOCLEAN is clearly superior to mechanical gantry solutions and the cleaning is finished faster.

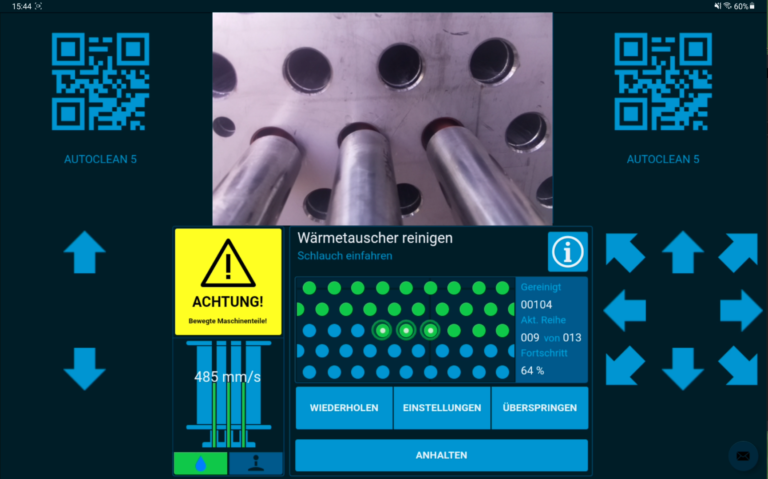

Scanning in 5 minutes and fully automatic cleaning – Coffee and Clean

Coffee during heat exchanger cleaning? No problem with AUTOCLEAN!

Only with AUTOCLEAN is complete automatic cleaning possible. The operating unit can be set up in a safe environment and after the short scanning process AUTOCLEAN 5 carries out the cleaning fully automatically.

Shielded from contamination, the beverage can be enjoyed in peace while monitoring the cleaning process. Even more enjoyable with the optional tablet and camera for full control.

Powerful support - Full control

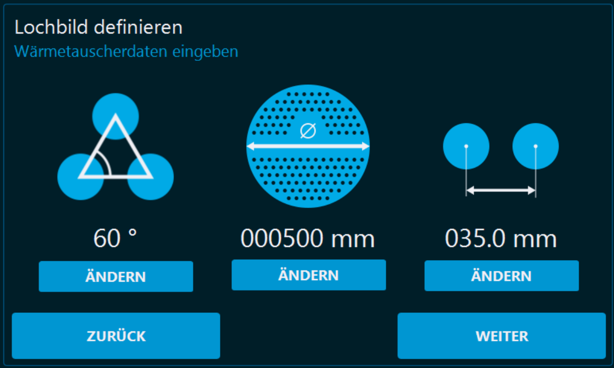

In addition to automatic scanning of the hole pattern, the AUTOCLEAN system offers other variants for entering the heat exchanger image. By entering a few parameters directly on the control unit, the system itself can be programmed in a few minutes.

Of course, AUTOCLEAN also has a semi-automatic mode that always assists the operator. After the pipe position has been entered, AUTOCLEAN automatically moves to the next position. Searching for the next pipe and manual positioning is thus no longer necessary.

In semi-automatic mode, AUTOCLEAN can also move the cleaning lances to the end of the heat exchanger and back on its own if desired.

Easy control of the feed rate

AUTOCLEAN 5 can precisely adjust the speed of the cleaning lances directly on the control unit, at a safe distance. In this way, the feed speed can be optimally adapted to the respective contamination and cleaning takes place efficiently with the ideal parameters. This does not require any conversion measures such as changing gears, and the air supply does not have to be throttled manually either.

AUTOCLEAN 5 continues to rely on pneumatic drives, which have a long service life even under the adverse conditions of industrial cleaning.

More information, camera and tablet optional

AUTOCLEAN 5 can be equipped with a tablet for extended operating and display options in addition to the proven control unit. Furthermore, one or more cameras can be integrated.

The tablet can be used to display the operator interface and to transmit images wirelessly. This makes it even easier to control the machine from a safe distance, and purely manual operation without visual contact is also possible.

Automatic oscillation

AUTOCLEAN 5 cleans the tubes of a heat exchanger adapted according to the contamination. If stubborn fouling is encountered inside a tube, the system reacts and starts an oscillating movement.

In contrast to a manually controlled cleaning lance, with AUTOCLEAN the nozzle is only retracted within the working range of the high-pressure water and thus no cleaning effect is lost.

Protocol after fully automatic cleaning, also available online

AUTOCLEAN 5 is IoT ready. If desired, the data from the protocol can be transferred directly from the construction site to a database, where it is available for an evaluation of the cleaning process. Triovent is currently working with Düsseldorf University of Applied Sciences on the HD-SmartClean project to systematically evaluate cleaning operations in order to leverage future potential for cleaning improvements and resource savings.

Maintenance flat rate - simple calculation of maintenance costs

We are convinced of AUTOCLEAN 5. Therefore, we can offer favorable service contracts with fixed annual flat rates for the maintenance of the system. Within the framework of the service contract, Triovent can take over the maintenance of the system at certain time intervals. Wear parts are replaced under the contract at no additional cost and Triovent guarantees the functionality of the AUTOCLEAN system when used properly. In the event of a failure, Triovent will provide a replacement unit.

Get to know it now!

We would be pleased to present our AUTOCLEAN 5 system live. A favorable variant to get to know AUTOCLEAN is to rent one of our systems for your next heat exchanger cleaning.